Production of electronic boards

Optimization of cleaning and final coating using surface chemical methods

With electronic printed circuit boards, sensitive interfacial contacts take place in various process sections and in an extremely restricted space, for example when making contact with the solder and with adhesive or coating substances. The quality of the preparatory cleaning can be ascertained by measuring the contact angle. Interfacial chemical methods also help to optimize the wetting and adhesion in a coating step.

Contact angle measurements for checking complete cleaning

Intensive cleaning is required between the many stations in printed circuit board production, from the coating of the carrier material with copper via etching and population to the final coating. This guarantees the wetting and adhesion between the surfaces which come into contact with one another in each case. Aqueous surfactant solutions, which remove troublesome hydrophobic residues such as flux by spraying or immersion, are normally used.

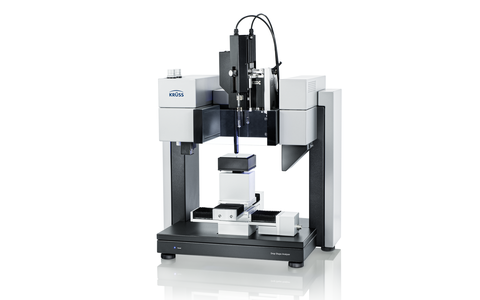

Our contact angle measuring instruments check whether a cleaning step has been successful. Homogeneously cleaned surfaces have the same contact angle everywhere; regions with hydrophobic residues usually exhibit a significantly higher value.

The Top View measuring method which we have developed even gives access to areas between components in the middle of the printed circuit board. This would be impossible to measure with the classical horizontal lens arrangement.

Tensiometry for quality assurance of cleaning solutions

Our tensiometers help in ensuring the quality of surfactants which are used for cleaning printed circuit boards. The result of the surface tension measurement enables the degree of wetting by the surfactant solution to be assessed. The efficiency of the surfactant is measured by means of the critical micelle concentration (CMC), which can be measured over a wide concentration range with a Force Tensiometer.

In addition, our bubble pressure tensiometers check the current surfactant content of the cleaner based on the dynamic surface tension. This quantity correlates with the concentration even when the surfactant content is high, and enables a reliable check to be carried out. A quick test can also be performed directly on site using our mobile measuring equipment.

Contact angle measurement for successful final coating

In order to protect the finished printed circuit board against environmental influences such as vibration, impact or moisture and therefore guarantee the functionality over a long period, the components are encapsulated with potting compound (glob tops). As well as good wetting, a high adhesive force and a low interfacial tension between component and potting compound are necessary for the stability of the coating. Our contact angle measuring instruments measure these quantities by measuring the surface energy and polarity of the components.

Super hydrophobic coatings are becoming ever more important, for example in the production of cell phones. Here, already completed printed circuit boards are sometimes provided with super hydrophobic coatings in order that a smartphone will still be in working order even after being completely immersed in water. The water-repellent character of such coatings can be determined by measuring the contact angle with water.