Adhesion on polymers

Contact angle and surface tension for optimizing plastic coatings

Plastics are materials with comparatively low surface free energy and correspondingly low interfacial adhesion when bonding, coating or printing. This applies particularly to water-based coating substances which tend to have a high surface tension. Both phases are frequently prepared for contact: the liquid coating substance by reducing the surface tension and the plastic by increasing the surface free energy. Both processes can be optimized with the help of our tensiometers and contact angle measuring instruments.

- Plastic bonding, particularly in the automobile industry and packaging

- Film printing

- Painting of plastics

- Adhesion of organic fibers and powders in matrix polymers with composite materials

Reducing the surface tension of the liquid coating substance

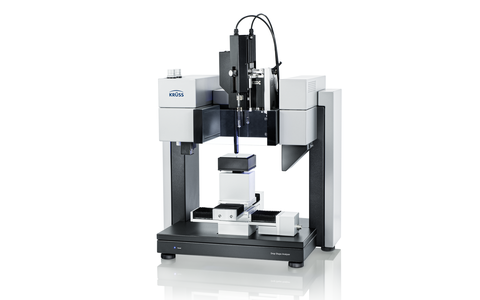

Paints and varnishes and even adhesives frequently contain surfactants which reduce the surface tension and therefore improve wetting. Our semi-automatic and fully-automatic tensiometers use precision methods for measuring the surface tension.

Our Force Tensiometers determine the efficiency of a surfactant based on the critical micelle concentration (CMC). This value indicates the maximum reduction in surface tension by a surfactant. Expensive overdosing can be avoided by measuring the CMC.

For rapid processes, our stationary and mobile bubble pressure tensiometers measure the rate at which the surfactant reduces the surface tension. The instruments measure the dynamic surface tension over a large time range right down to a few milliseconds. The results help in selecting or developing ideal surfactants which are matched to the process speed.

Increasing the surface free energy of the plastic

Good wetting alone does not produce good adhesion. To achieve this, the surface free energy of the plastic is often increased by pre-treatment. Common methods here are plasma, corona or flame treatment and the effect of oxidizing gases such as ozone or fluorine.

Our drop shape analysis measuring instruments can measure the increase in surface free energy during the treatment process based on the contact angle with several liquids. At the same time, the polar fraction of the surface free energy, which reflects the required plastic activation due to the incorporation of polar groups in the surface, is also determined. Our mobile solutions also enable non-destructive measurement to be carried out on site on samples of any size. Repeat measurements are carried out to check the long-term effect of the treatment.

Calculating the adhesion and long-term stability

The work of adhesion can be calculated as a direct measure of the adhesion based on combined measurements of the surface free energy of the polymer and the surface tension of the liquid phase. Both components can be optimized to achieve the required contact thanks to the separate analysis. The measuring methods as a whole are described in the standard DIN 55660 for coating substances.

A further result obtained from the combined surface investigations is the interfacial tension, which describes the inherent instability of a coating. The lower the interfacial tension, the lower the tendency of the layer to become detached due to other substances which penetrate the layer through tiny cracks.

Measurements on fibers and powders

Contact angle, surface free energy, and work of adhesion can also be determined on fibers and powders, for example in the quality assurance and development of fiber reinforced materials. Fibers and powders under investigation can be coated plastics as well as materials in which polymers form the coating.

Our Tensiometers are capable of measuring very small wetting forces, which occur at filaments, in order to determine the contact angle.